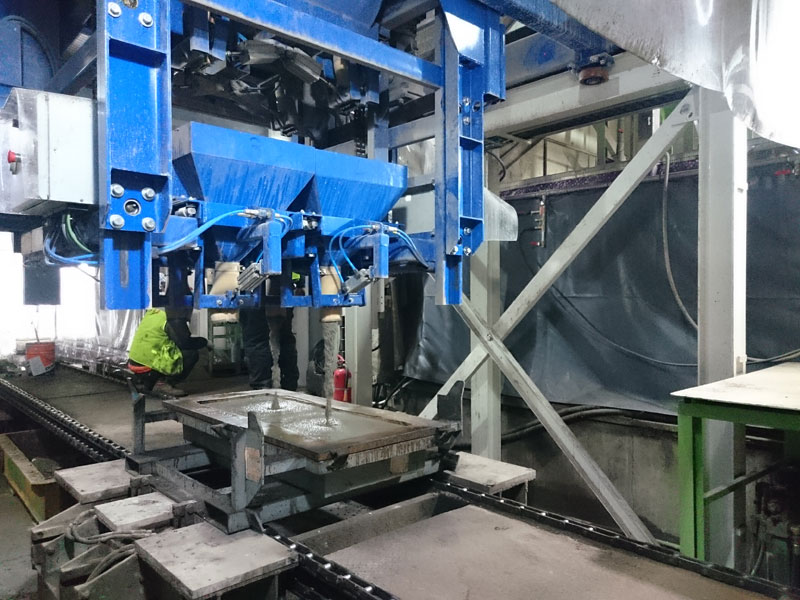

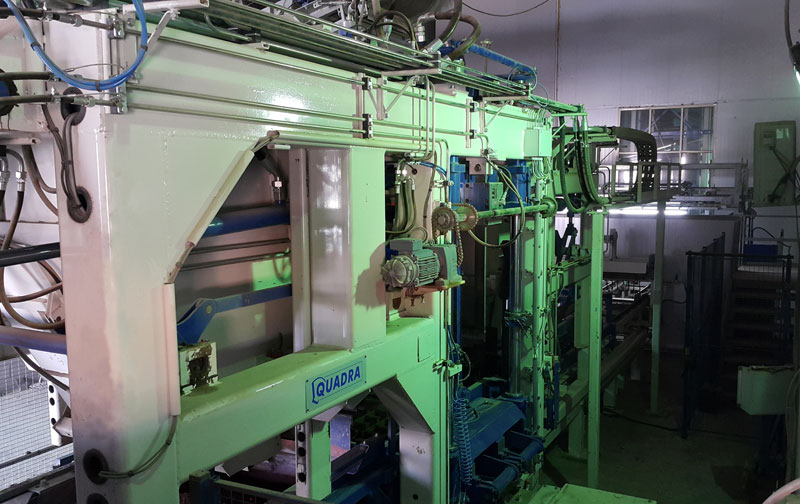

Created in 1988 by Mr Pascal Leandri, the company Prefabeton, based on the island of Reunion in France, is specialised in precast concrete products designed for road works, building, construction and public works. Prefabeton has successfully ensured its leading position by investing in effective production equipment. The leading manufacturer within its area, Prefabeton has enlarged its products range over the years: slabs, pavers and kerbstones with high added value, blocks, vegetative retaining walls, manholes, gutters, rainwater scuppers and other concrete products designed for companies, craftsmen, municipalities and private individuals. In 1997, Prefabeton became the first company on the island of Reunion to obtain the standard called “NF” for its manhole range. This quality process is now applied to all its products, along with CE branding in order to provide its customers with certified products. The first collaboration between Prefabeton and Quadra was in 1999 when Prefabeton bought their first production unit with block machine. This long-standing client has recently commissioned the equipment manufacturer Quadra with a large-scale project: the manufacturing of solid products with semi-dry demoulding by turning over, through a fully-automated process. This production was originally ensured by its operators working on machine type vibrating tables or small rollover machines. The main production for which this new equipment was intended was the manufacturing of manholes and seating rings and extended to other products such as low walls, retaining building blocks, drainage channels and other products with suitable dimensions for the curing chambers.